Kanban session

Introduced at Toyota in the 1950s, the Kanban method aimed to improve production based on just-in-time and scalable processes.

Today, it is both a project management method and a tool, guided by two principles: visual and real-time. For this, teams work with tables and post-it notes, called labels. This methodology provides for a production system based on demand rather than supply.

The customer orders, the supplier produces to meet his demand. It avoids overproduction and therefore unsold products, limits storage costs, enables processes to be improved as and when necessary and allows a product defect to be quickly corrected or a problem in the production chain to be resolved. On the other hand, this method is not suitable in sectors where orders vary a lot (strong seasonality for example) since no stock can respond instantly to demand.

Today, the Kanban method is used in companies to enable better management of tasks between team members. It allows both a more Agile organisation and an empowerment of the work. The Agile method can take many forms, the two most common being Scrum and Kanban. The whole operation is based on tags, which are intended to optimise production and collaboration between teams. A label (Kanban, in Japanese) is created as soon as an order is placed.

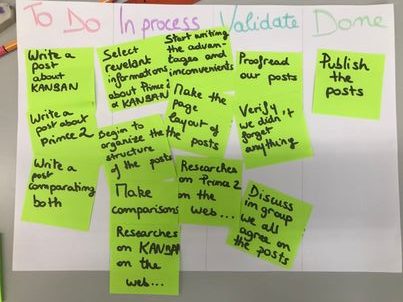

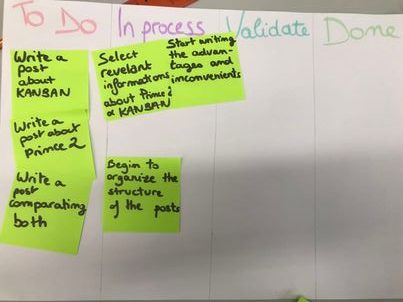

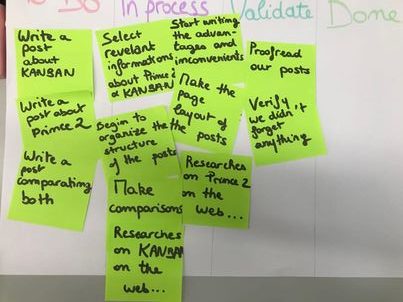

It indicates a task to be carried out (a feature to be developed on a back office for example). The tasks are divided into a table according to their status and can be moved from one column to another as the process progresses: for example, under consideration, to be done, in progress, done. This way, each team member knows what he or she has to do and where the others’ work stands.

In addition to improving communication, this post-it technique provides a clear overview of the entire production chain and the progress of tasks, making it easy to spot blockages and emergencies.

Before

During

End